ending work in process inventory calculation

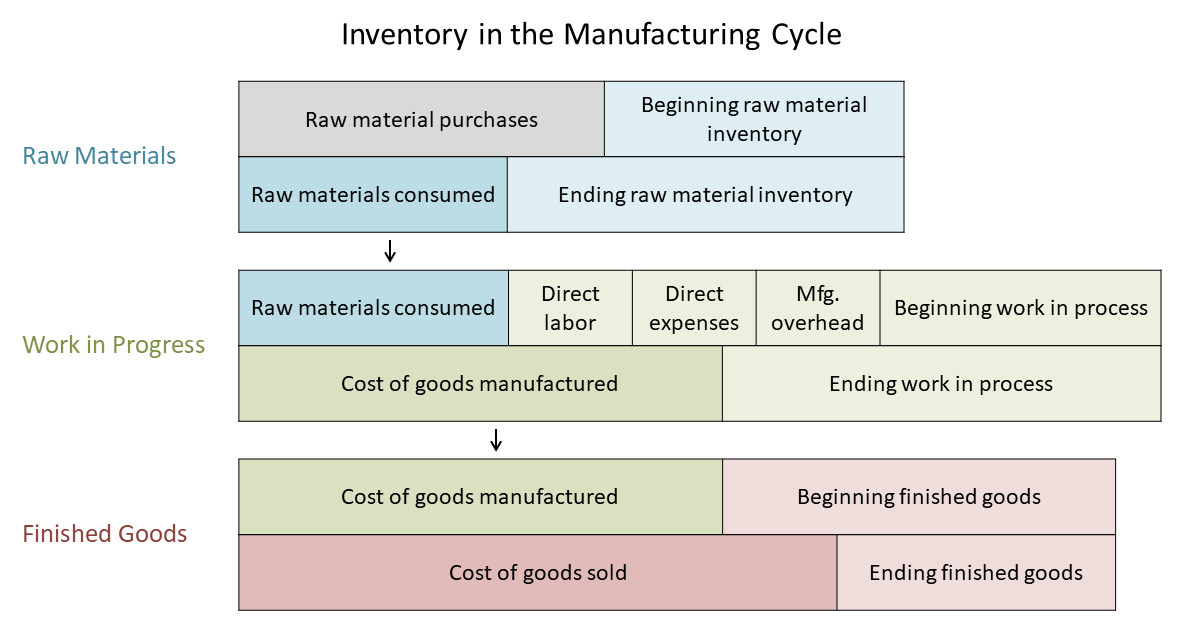

Ending WIP Beginning WIP Costs of manufacturing - costs of goods produced. Ending WIP Inventory Beginning WIP Inventory Production Costs Finished Goods Cost.

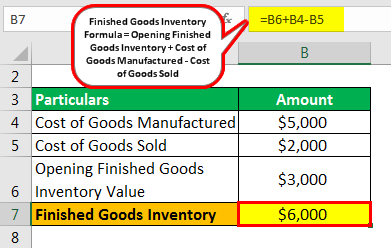

How To Calculate Finished Goods Inventory

This ending inventory figure is listed as a current asset on a balance sheet.

. Take a look at how it looks in the formula. Find the cost of goods available. Amount of Goods in Stock x Unit Price Ending Inventory.

Heres how it looks. Calculating Your Work-In-Process Inventory. Work in process inventory is an asset The ending work in process inventory is simply the cost of partially completed work as of the end of the accounting period.

Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs - Cost of Finished Goods. WORK IN PROCESS INITIAL WORK IN PROCESS DIRECT LABOR OVERHEAD - COST OF FINISHED GOODS. You can do this by adding the cost of your beginning inventory with the cost of all purchases.

How to Calculate Ending Work In Process Inventory The work in process formula is. The ending Inventory formula calculates the value of goods available for sale at the end of the accounting period. The formula for ending work in process is relatively simple.

Answer of Calculate the ending Work in Process Inventory balance on June 30. Subtract the estimated cost of goods sold step 2 from the cost of goods available for sale step 1 to arrive at the ending inventory. How do you calculate work in process inventory balance.

How do you calculate ending work in process inventory. Ending work-in-process 500 beginning work-in-process inventory 1700 total manufacturing costs for the period - 1500 total cost of goods manufactured for the period. After the beginning WIP inventory is determined along with the manufacturing costs and the COGM its easy to calculate the amount of WIP inventory that you currently have.

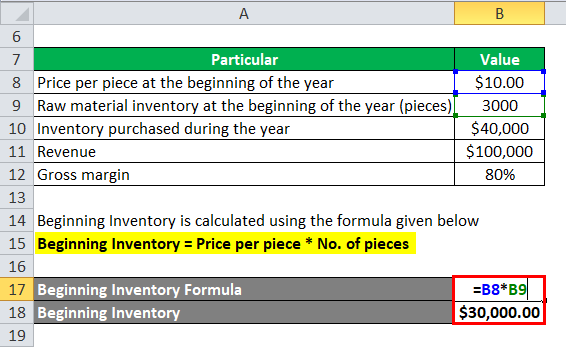

Find the cost of goods sold. Here are the steps for using the gross profit method of calculating ending inventory. Usually it is recorded on the balance sheet at a lower cost or its market value.

Find the ending. Work In-process Inventory Example. To calculate WIP inventory you need the beginning work in process inventory and to calculate that you need the ending work in process inventory.

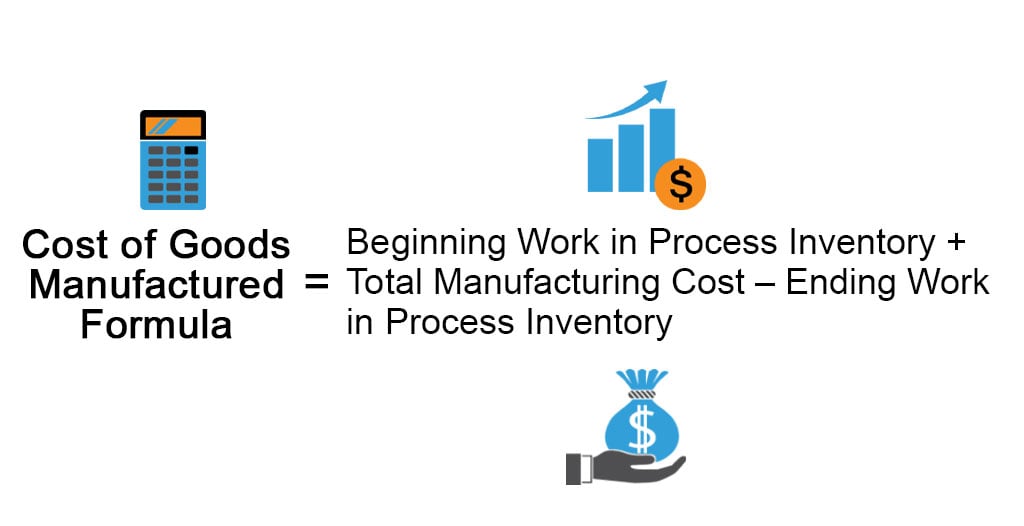

Beginning WIP Inventory Manufacturing Costs COGM Ending WIP Inventory. Multiply the number equivalent units on hand by the value you would assign to finished-goods inventory to determine the balance of WIP inventory. Formulas to Calculate Work in Process.

Formulas to Calculate Work in Process. How do you calculate ending inventory units. Therefore the formula to calculate the Work in Process WIP is.

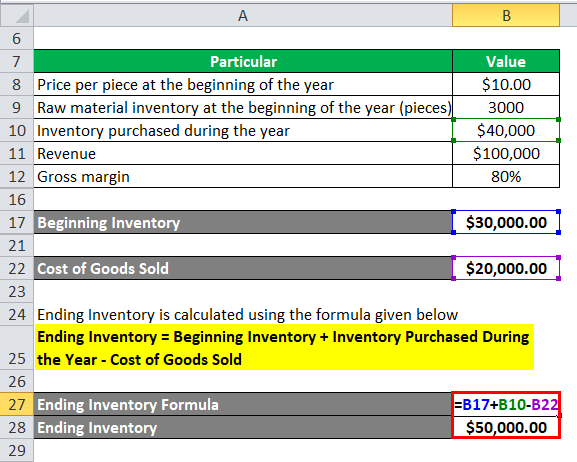

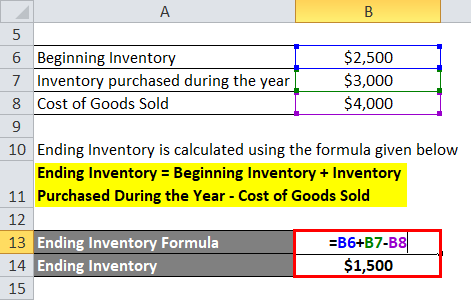

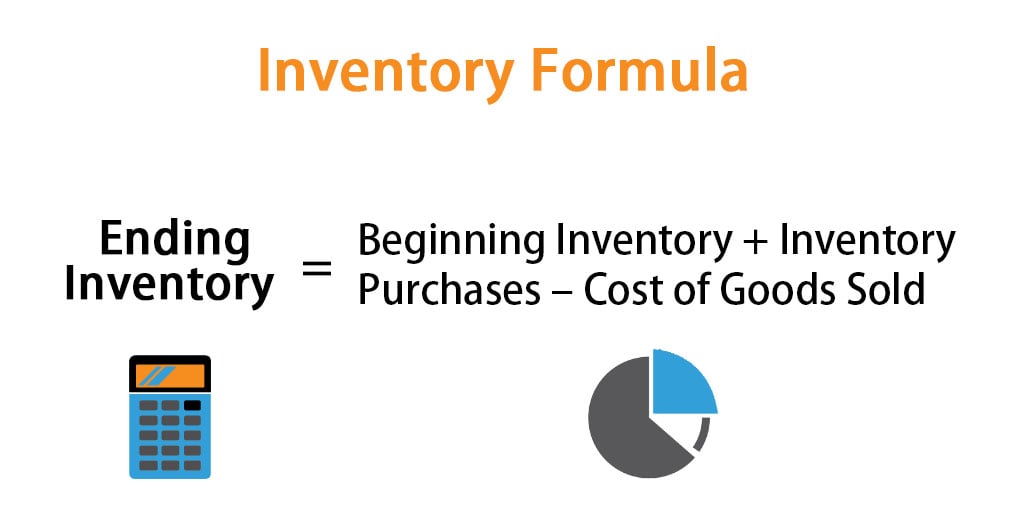

WIP e WIP b C m - C c. The last quarters ending work in. Ending Inventory beginning inventory net purchases - prices of products sold Ending Inventory 30000 35000 - 45000 Add together the beginning inventory and net purchases and subtract the prices of products sold from their sum and you get the value for the ending inventory as shown below.

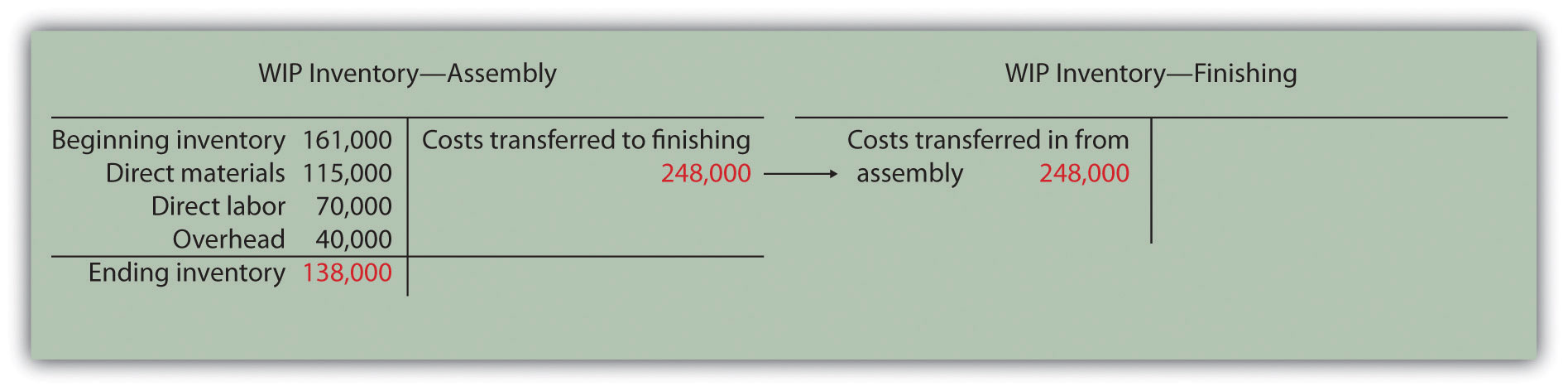

The difference between the sum of the beginning work in process and the costs of manufacturing is the ending work in process. The process of converting raw materials into finished products costs your company in time and money. Ending WIP Beginning WIP Materials in Direct Labor Overheads - COGM Ending WIP 25000 40000 10000 5000 - 45000 Ending WIP 35000.

Most businesses that are not run by experienced operations management experts will have too much work in process. Assume Company A manufactures perfume. In this equation WIP e ending work in process.

Ignoring work in process calculations entirely. The formula for calculating the WIP inventory is. The ending work in process is now calculated using the work in process inventory formula as follows.

Formula to Calculate Ending Inventory. Each accounting cycle starts with an amount for the beginning work in process. Subtract the estimated cost of goods sold step 2 from the cost of goods available for sale step 1 to arrive at the ending inventory.

Additional Business Financial. Beginning WIP DM DL MOH Cost of goods manufactured Ending WIP. Multiply 1 expected gross profit by sales during the period to arrive at the estimated cost of goods sold.

Thus your ending WIP inventory comes out to be 100000 for the year. Ending Inventory Beginning Inventory Purchases -Cost of Goods Sold COGS. The result is the.

Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs- Ending WIP Inventory. Total Manufacturing Costs Beginning WIP Inventory Ending WIP Inventory COGM. How to Calculate Ending Work in Process Formula Beginning Work in Process.

To calculate your in-process inventory the following WIP inventory formula is followed.

What Is Work In Process Wip Inventory How To Calculate It Ware2go

Work In Process Wip Inventory Youtube

Finished Goods Inventory How To Calculate Finished Goods Inventory

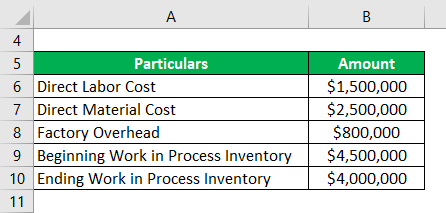

Cost Of Goods Manufactured Formula Examples With Excel Template

All You Need To Know About Wip Inventory

How To Calculate Ending Inventory The Complete Guide Unleashed Software

Manufacturing And Non Manufacturing Costs Online Accounting Tutorial Questions Simplestudies Com

Work In Progress Wip Definition Example Finance Strategists

Ending Inventory Formula Calculator Excel Template

Ending Inventory Formula Calculator Excel Template

Wip Inventory Definition Examples Of Work In Progress Inventory

Manufacturing And Non Manufacturing Costs Online Accounting Tutorial Questions Simplestudies Com

Inventory Formula Inventory Calculator Excel Template

Cost Of Goods Manufactured Formula Examples With Excel Template

Work In Process Inventory Formula Wip Inventory Definition

Finished Goods Inventory How To Calculate Finished Goods Inventory

What Is Work In Process Wip Inventory How To Calculate It Ware2go